Driven by high-energy-consumption applications such as AI data centers and electric vehicles, global energy demand is surging. However, the core bottleneck for technological upgrades lies in the energy efficiency, power density, and durability of power semiconductors. onsemi introduces vGaN power semiconductor technology, bringing revolutionary solutions to the global high-power application field. Leveraging the exclusive GaN-on-GaN architecture and multiple performance breakthroughs, the new generation of power semiconductors enables current to flow vertically through the compound semiconductor, achieving higher operating voltages and faster switching frequencies. This helps design more energy-efficient, lighter, and more compact systems for areas such as AI data centers, EVs, renewable energy, and aerospace.

GaN-on-GaN Exclusive Architecture Power Semiconductor

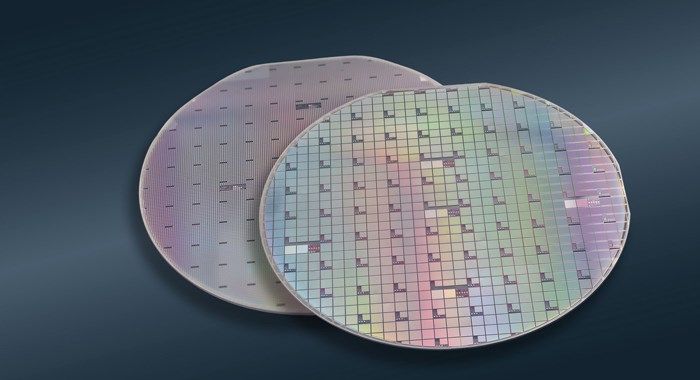

This technology is researched, developed, and manufactured at onsemi's wafer fab in Syracuse, New York, covering over 130 patents in fundamental processes, device architecture, manufacturing, and system innovation. Its core advantages lie in the precise manufacturing process and unique material properties:

In highly controlled furnaces exceeding 1000°C, atoms are deposited layer by layer with a precision of one billionth of a meter per layer, achieving crystal uniformity.

GaN's inherent hexagonal wurtzite structure, with gallium and nitrogen atoms stacked alternately, gives it unique electronic and optical properties far surpassing those of cubic silicon.

Currently, most GaN devices on the market primarily use silicon or sapphire substrates. In contrast, onsemi's vGaN employs a monolithic GaN-on-GaN design, allowing current to flow vertically through the chip body rather than along the surface. This fully unleashes the performance potential of the gallium nitride material, granting it advantages of higher withstand voltage capability, higher power density, and stronger energy efficiency performance.

"Vertical GaN is a game-changer for the industry and cements onsemi’s leadership in energy efficiency and innovation. As electrification and AI reshape industries, efficiency has become the new benchmark that defines the measure of progress. The addition of vertical GaN to our power portfolio gives our customers the ultimate toolkit to deliver unmatched performance. With this breakthrough, onsemi is defining the future where energy efficiency and power density are the currency of competitiveness." Dinesh Ramanathan, Senior Vice President of Corporate Strategy, onsemi.

onsemi also revealed during its earnings conference call that the first-generation vertical gallium nitride products are currently being sampled and tested. They are currently developing the second-generation products and expect to start generating revenue around 2027.

vGaN Power Semiconductor Technology Brings Breakthroughs for High-Power Applications

Test data shows that vGaN devices can easily withstand 1200V and higher voltages, achieving higher energy efficiency when switching large currents at high frequencies. High-end power systems built based on this technology can reduce energy loss by nearly 50%, while its higher frequency operating characteristics can also reduce the volume of passive components such as capacitors and inductors by about half. In addition, vGaN devices are about two-thirds smaller in volume compared to existing lateral gallium nitride devices. Therefore, this technology is very suitable for high-power application scenarios with stringent requirements for power density, thermal performance, and reliability.

AI Data Center Field

With the explosive growth in computing power demand, the power consumption of some data centers has already surpassed that of small and medium-sized cities. The power density and cost control of 800V DC-DC converters have become key to breakthroughs. vGaN technology significantly increases converter power density by reducing the number of electronic components, substantially optimises cost per rack, and provides efficient energy support for AI computing power expansion.

Electric Vehicle and Charging Infrastructure Field

vGaN technology can create smaller, lighter, and more efficient onboard inverters, directly increasing vehicle range. Simultaneously, it enables faster, more compact, and more robust charging equipment, breaking through the industry bottlenecks of "slow charging and large equipment" for electric vehicles.

Renewable Energy and Energy Storage Systems

The high-voltage handling capability and low energy consumption advantages of vGaN can improve the energy conversion efficiency of solar and wind power inverters, providing fast, high-density bidirectional power supply for battery converters and microgrids, facilitating the large-scale application of clean energy.

Industrial Automation Field

The characteristics of Onsemi's new generation vGaN power semiconductors enable the development of motor drives and robotic systems with smaller size and better heat dissipation.

Aerospace Field

Its high reliability, strong robustness, and compact design characteristics are helping the aerospace and defense security fields build next-generation high-performance equipment.

Conclusion

Currently, 5000V to 10,000V-class vertical structure GaN diodes and 1200-1700V vGaN transistors have entered the semiconductor market. With the improvement in quality and reduction in cost of GaN substrates and epitaxial materials, vGaN devices are expected to maximize the advantages of GaN materials in specific scenarios, moving from the laboratory to the market.